Model PQBS-D

SWL: Up to 15 tonnes

Wheel-drive system: Hydraulic

Quad wheel-drive units: Tilting and adapting to different hull shapes

Slipway operation: Semi-automatic with single-operator

Slipway slope length: According to customers' request

Slipway angle: Up to 12° slope angle

Slipway access/entrance: Via submerged wheel units on slipway cradle

Boat guiding system: Tilting quad wheel-drive units and guide bumpers

Slipway cradle dimensions: Designed to purpose and vessel interface

Slipway cradle suspension: Load bearing travelling rails

Slipway cradle movement: Hydraulic operated rack and pinion drive system

Max. frame outreach: Designed to vessels waterline

- Remote control from daughter craft

- Various remote control options on vessel side

- Power and control system redundancy

- Emergency launch and recovery by accumulator and UPS

- Parking position for additional boat(s)

- Higher slope angle and/or SWL (if possible/feasible)

Slipway and stern entry systems with quad wheel-drive units

PALFINGER's hydraulically powered, semi-automatic Slipway System consists of several wheel-drive units (quad units) in two (or multiple) rows that rotate on axes to automatically adapt the slipway to the hull shape of a daughter craft during launch and recovery operations.

A daughter craft can engage the slipways at a range of speeds, up to seven knots higher than the speed of the mother vessel with some systems. When a boat enters the slipway the overrunning clutches allow free rotation of the wheels in the recovery direction until the boat speed and whee-drive speeds match.

At that point, the hydraulically powered wheel-drive units take over under single-operator control and dock the daughter craft safely inside the slipway. End stoppers automatically set the craft in parking and stowage positions and engage failsafe brakes on the wheel-drives.

MAX. SEA STATE FOR SLIPWAY OPERATIONS

The structural strength of the system is high and is normally not the limiting factor. Test and operational use of PALFINGER Slipway Systems have been performed in Sea States above seven with the mother vessel steaming ahead at low speed.

Safe operations at high Sea States are highly dependent on:

- Mother vessel heading and speed

- Mother vessel responsiveness (RAO Profile)

- Waves and wind pattern

- Boat driver’s skills

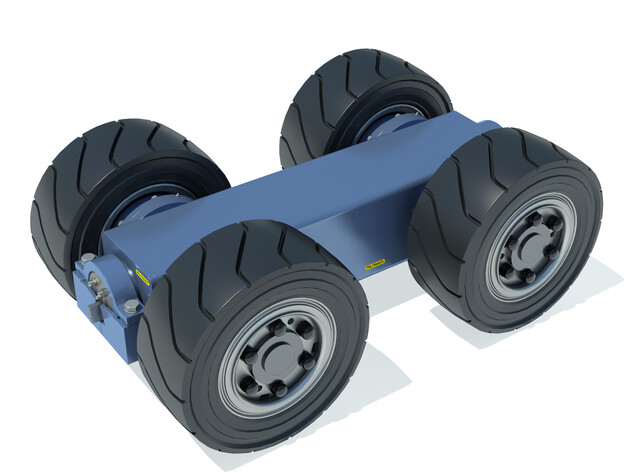

QUAD WHEEL-DRIVE UNITS

Wheel-drive unit configuration: 4 wheels on each wheel-drive unit

Brakes: 1 for each wheel

Hydraulic motors: 1 for each wheel

Over-running clutches: 1 for each wheel

Number of quad wheel-drive units: Depending on length of slipway

Length of quad wheel-drive units: 1,526 mm

Width of quad wheel-drive units: 960 mm

Wheel diameter: Ø 600 mm

Wheel-drive units tilt mechanism: 2x Bearing arrangement

Wheel-drive unit tilt range: +/-20°

Max. freewheel speed, inlet: 0-240 m/min (0-7 knots)

Max. freewheel speed, outlet: 0-35 m/min (0-1.1 knots)

Drive assist speed, in and out: 0-25 m/min (0-0.8 knots)

Max. depth for installation: 2 meter below water surface

Max. load, each wheel: 4 tons

Weight (each wheel-drive unit): Approximately 725 kg