- Home

- Deck Equipment

- Slipway and Stern Entry Systems

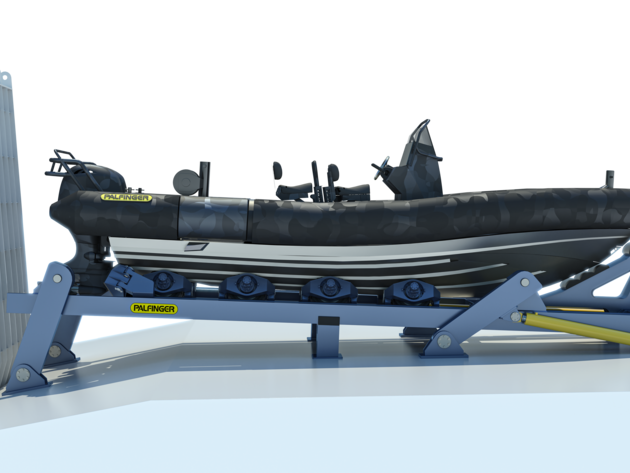

- Model PSWS-T-D

Model PSWS-T-D

SWL: Up to 6 tons

Wheel-drive system: Hydraulic

Single wheel-drive units: Manually adjustable wheel angle to adapt to different hull shapes

Boat length: 6 - 12 meter

Slipway angle: Up to 12o slope angle

Slipway access/entrance: Via submerged wheel-drive units on slipway cradle

Boat guiding system: Boat guide and deflector plates at slipway entrance

Slipway frame dimensions: Designed to purpose and vessel interface

Slipway frame suspension: Load bearing tilting arms

Slipway cradle movement: Hydraulic cylinder driven tilt and drive mechanism

Max. frame outreach: Designed to vessels waterline

Power supply for frame and cradle: Via energy chain

- Remote control from daughter craft

- Various remote control options on vessel side

- Power and control system redundancy

- Emergency launch and recovery by accumulator and UPS

- Multi-axis adjustment of wheel-drive units

- Higher slope angle and/or SWL (if possible/feasible)

Slipway and stern entry systems with single wheel-drive units

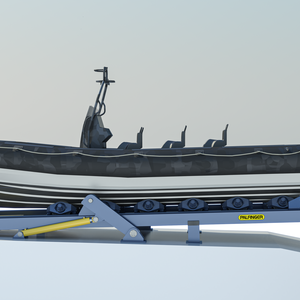

PALFINGER’s hydraulically powered, semi-automatic Slipway System consists of several single wheel-drive units in parallel rows. The tilt, height, and distance between the wheels can be manually adjusted to conform to a range of daughter craft hulls.

A daughter craft can engage the slipways at a range of speeds up to seven knots higher than the speed of the mother vessel. When a boat enters the slipway, the overrunning clutches allow free rotation of the wheels in the recovery direction until the boat speed and wheel-drive speeds match.

At that point, the hydraulically powered wheel-drive units will take over under single-operator control and dock the daughter craft safely inside the slipway. End stoppers automatically set the craft in parking and stowage positions and engage the fail-safe brakes on the wheel-drives.

MAX. SEA STATE FOR SLIPWAY OPERATIONS

Test and operational use of this slipway system have been performed in Sea States 3 with mother vessel steaming ahead with low speed.

Safe operations at higher Sea States may be possible but is highly dependent on:

- Stern entry arrangement

- Mother vessel heading and speed

- Mother vessel responsiveness (RAO Profile)

- Waves and wind pattern

- Boat driver’s skills

SINGLE WHEEL-DRIVE UNITS

Wheel-drive unit configuration: 1 wheel on each wheel-drive unit

Wheel angle and transverse spacing: Manually adjustable

Brakes: 1 for each wheel

Hydraulic motors: 1 for each wheel

Over-running clutches: 1 for each wheel

Number of single wheel-drive units: Depending on length of slipway

Wheel diameter: Ø 434 mm (Foam filled)

Max. freewheel speed, inlet: 0-240 m/min (0-7 knots)

Drive assist speed, in and out: 0-25 m/min (0-0.8 knots)

Max. slipway slope angle: Up to 12°

Max. payload for slipway: Up to 12 tons

Max load, each wheel: 2 tons

Weight (each wheel-drive unit): Approximately 420 kg